Vacuum Burst Leak Test

What is a Vacuum Burst Leak Test?

The Vacuum Burst Leak Test is useful for testing check valves, relief valves, seal strength and package integrity. This test requires evacuating a product slowly through a flow valve. After the burst, the pressure rapidly increases to atmospheric pressure. The tester captures the pressure immediately before the product ruptures/opens to atmosphere.

How is a Vacuum Burst test performed?

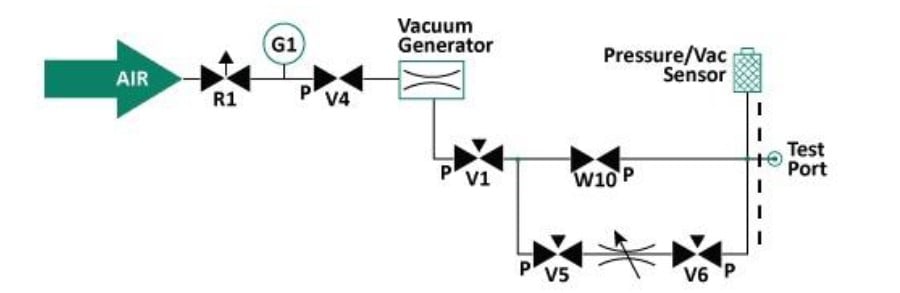

The test starts by first attaching the product to the test port. Next, positive pressure is applied to vacuum generator through V1 and the vacuum level is set by pressure regulator R1.

Valve V10 closes and valves V5 and V6 open to slowly pressurize the product through the precision flow control FC. Sensor S1 measures the vacuum. The instant the product ruptures or opens, the tester records the highest vacuum level attained and displays that pressure on the run display.

At the end of the test, vacuum is released to atmosphere through valve V10 and V1 to ensure no vacuum remains in the test circuit. A vacuum decay test can be run following the vacuum burst test by opening valve V1, V4 and V10 to fill the product. Valves V5, V6 and V10 remain closed during the test. Vacuum is trapped between the product and the sensor. At the end of the test, vacuum can be dumped at valve V1 and V10.

Testers Supporting Vacuum Burst Leak Tests

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)