Sealed Component Leak Test

What is a Sealed Component Leak Test?

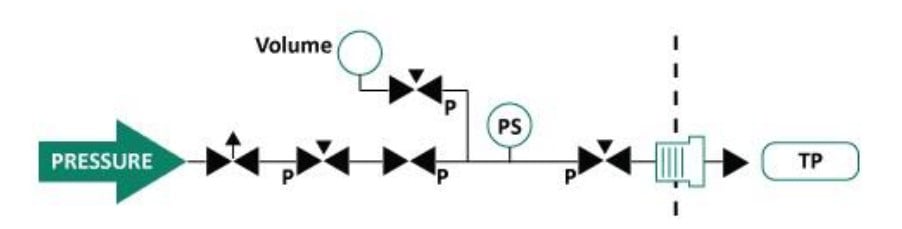

Also referred to as a Sealed Component Challenge, Volumetric, or Volume Verification test, the Sealed Component Leak Test is used to test parts that are sealed and do not have a port to depressurize. This test pressurizes a metered volume and then shares this quantity of air with the test chamber. The resulting change in pressure depends on the total volume, which is application specific and comprises the metered volume, connecting pipework and the free space around the test part in the chamber.

A greater than expected pressure change is an indication that the test part has a gross leak and fails this test and cause the test sequence to terminate. Test parts that pass will go onto the classic leak test cycle for fine leaks.

How is a Sealed Component Test Performed?

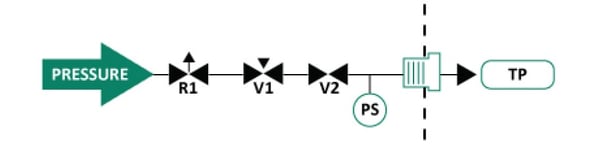

The Sealed Component test includes the following steps:

- Fill

- Stabilize

- Test

The Fill step operates a valve to pressurize only the metered volume connected to it. A larger pressure change occurs for leaking components. The resulting pressure drop depends on the metered volume, test component volume and the dead volume within the test chamber (i.e. test chamber volume minus test component volume) which are application dependent.

Next, the Stabilize step operates a valve to isolate the regulator from the metered volume. Finally, the Test step energizes the selected channel valves to connect the test part to the pressurized volume. During this step the resulting pressure change is shown as a delta value in the test value fields.

Fill, Stabilize and Test Demonstration

Sealed Component Leak Test Scenario

Testers Supporting Sealed Component Tests

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)