Mass Flow Leak Test

What is a Mass Flow Leak Test?

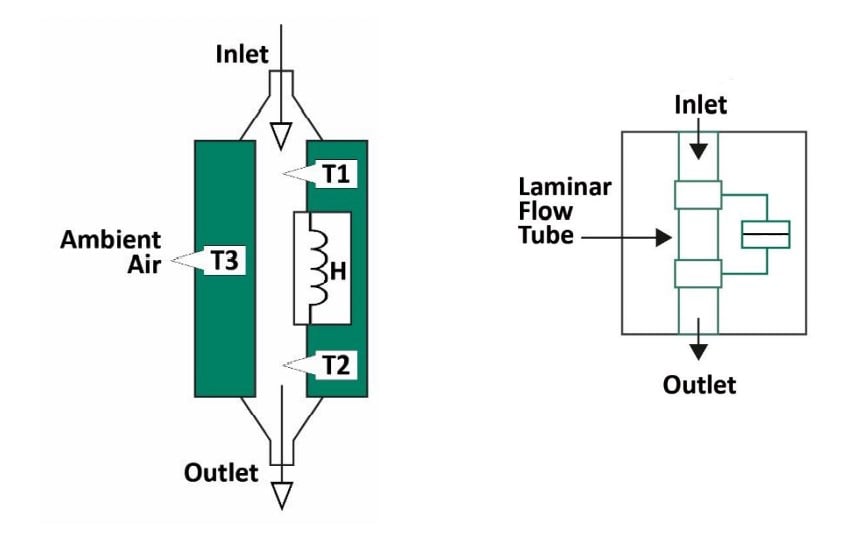

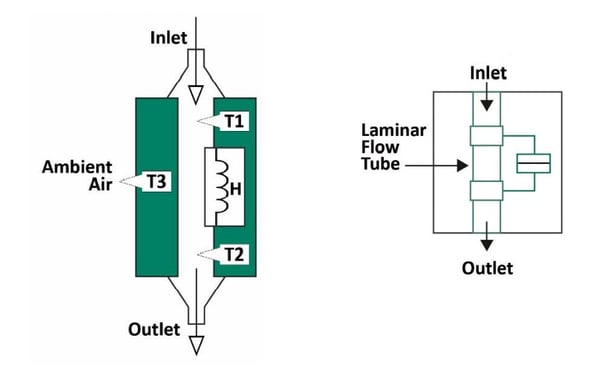

The mass flow leak test measures the amount of air passing through an object using units of measurement of sccm or liters/time period. The major advantage of the mass flow technique is that it eliminates the need to know the volume of the product. There are two mass flow sensing techniques that have found their way in to leak and flow testing: thermal mass flow and differential sensing mass flow. Differential sensing mass flow, or laminar flow, is not to be confused with differential mass flow leak testing

How is a Mass Flow test performed?

You will first Chose the preset test – Mass Flow from the test menu on the tester and enter the test pressure into the program.

Next, the product is attached and the test is started. The air moves into the inlet port and the precision micro-thermistor (T1) measures the temperature of the inlet air.

As the test continues, the flow sensor’s heater (H) increases the temperature of the moving air far above room temperature as measured with the sensor T3. Temperature of the outgoing air is measured at the next precision micro-thermistor, T2.

Temperature difference of T2 minus T1 is proportional to the ability of the air mass to transfer heat. The read out is in mass flow units, such as sccm.

Testers Supporting Mass Flow Tests

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)