Laminar Flow Leak Test

What is a Laminar Flow Leak Test?

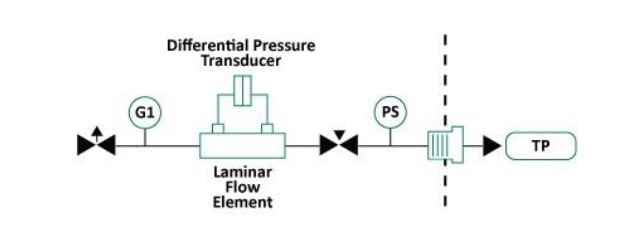

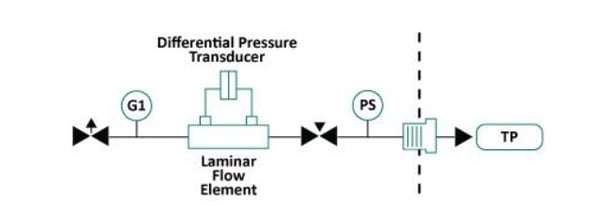

The Laminar Flow leak test is a sensitive flow technique that is commonly used on large volumes where the leak integrity specification is high, for example exhaust assemblies and sub-assemblies. This method uses a calibrated flow element that relies on the laminar flow across two ports and compares the pressure difference between these ports which is proportional to flow rate.

How is a Laminar Flow test performed?

First, the fill valve is opened to allow flow across the laminar flow element and through the test part. Once the desired pressure is achieved, the measure phase is entered. Any flow through the flow element will register as a pressure difference. A large flow will register as a large difference in pressure between the ports which is proportional to the flow rate. A restricted flow through the part will increase back pressure which will indicate a lower pressure difference, hence a lower flow.

Testers Supporting Laminar Flow Tests

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español