Solving Complex Testing & ISO 80369 Compliance Requirements for Luer Connector Applications With JUMP, MATH & STEP

A luer connector is a small apparatus that enables the connection of intravenous drug delivery devices and accessories. It might be fair to say that this little invention has improved patient safety like no other and is helping to standardize connectivity in a large part of the medical device industry. Overuse of luers have been the cause of connectivity mistakes and the need to control design and specifications. This is achieved by compliance with ISO 80369 Small Bore Connector Standards, of which there are several subsets that deal with specific types of medical devices including ISO 80369-7 which covers luer connectors and ISO 80369-20 which describes common test methods.

ISO 80369-7 states that:

“Luer connectors shall be evaluated for leakage using either the leakage by pressure decay test method or the positive pressure liquid leakage test method.”

“Luer connectors evaluated for fluid leakage by pressure decay test method shall not leak by more than 0.005 Pa*m3/sec while being subject to an applied pressure of between 300 kPa and 330 kPa over a hold period between 15s and 20s using air as the medium. Manufacturers may use a greater pressure.”

Compliance may be checked by using the tests specified in Annex B of ISO 80369-20. These require the reporting of the pressure change and the leak rate.

Overcoming Vulnerabilities of Human Error Using Automatic Leak Testing Equipment

A long-time medical device manufacturing client reached-out to Uson to supply a leak test instrument capable of facilitating compliance with part 20, and automatically calculate measurements that can be time consuming and vulnerable to human error.

Some of the other specific requests included:

- Pressure and vacuum decay measurements

- Automatically calculate the test part and test circuit volume in m3

- After completing the pressure change measurement and volume calculations automatically calculate the test part leak rate in Pa*m 3/sec

- Then compare the calculated leak rate to the specification’s maximum allowable and provide a clear Accept or Reject decision to the operator

- Use engineering units as called out in the specification

- Follow specification as close as possible to eliminate the need to request a process deviation

- And let’s not forget they requested the data for all steps in the process be stored to their server

These are the laws of physics that were used to satisfy our customer’s requests:

Ideal Gas Law Review

- Leak testing techniques are strongly influenced by the physical properties of gases

- The behavior of a gas can be expressed with the basic Ideal Gas Law (Emile Clapeyron in 1834) PV = nRT. The state of an amount of gas, n, is determined by pressure, volume and temperature.

Boyles Law Review

- Leak Rate Formula can then be tweaked to solve for volume if Leak Rate and Pressure Change are known. For Example:

- Leak Rate: 3 cc/min

- Time: 10 seconds (.16667 Minutes)

- Atmos. press.: 1013.2 mbar

- Press. Change: 20 mbar

- Total Volume =25.33 cc

Uson Leak Testing Solution for ISO 80369 Compliance: Optima vT

Uson Leak Testing Solution for ISO 80369 Compliance: Optima vT

The Optima vT air leak tester was chosen for this application because of its powerful PROGRAM JUMP, MATH and STEP functions. By working closely with the client’s quality assurance and regulatory affairs teams our application development team developed a series of program steps and register entries that would perform the necessary calculations automatically and, using the clients own accept reject criteria, segregate good and bad parts by pass and reject results.

To solve the leak rate equations and make the Accept/Reject decision the following Optima vT step types were utilized:

- Measure Pressure Change- Calculating Volume & Pressure Leak Rate

- MATH- Calculating Volume

- Measure Vacuum Change- Calculating Vacuum Leak Rate

- MATH- Calculating Leak Rate

- MATH- Engineering Unit Conversions

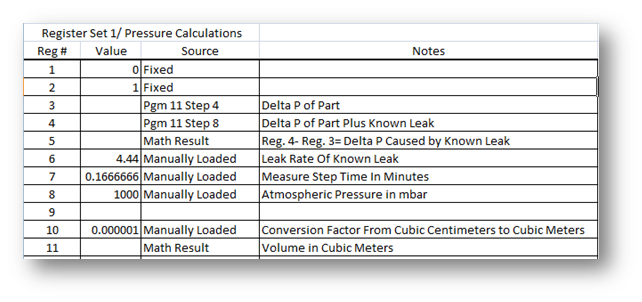

Below is a snippet of the OptimavT register Set 1 showing some of the registers used to perform these tasks:

*The above snippet is only a few lines of register entries and calculations.

It is anticipated this will save the customer hundreds if not thousands of man hours in the lab by automating the compliance check of their products to this specification. How many hours might you save with a setup such as this?

This application is an excellent example of the thinking behind the design of the Optima vT . Our product development team designed an instrument so versatile that it can combine the attributes of a leak tester, a PLC and a computer in one neat package.

For aiding compliance, taking the headache out of leak test calculations, removing the scope for human error, and providing fast, reliable results to complex problems, OptimavT is the answer.

Uson can help!

If you need assistance with a luer connector or other complex leak or flow testing application the experts at Uson can help. We've partnered with thousands of medical device manufacturers' Quality Assurance and Regulator Compliance personnel to identify the best leak measurement equipment and test method to enable compliance and and speedy 510(k) applicaiton approval. We can help you too! Contact us today!