Quantified Leak Rate Using Mass Flow

How to convert bubbles to flow units using a quantified leak rate with the mass flow test method.

Products such as catheter balloons, one-way valves, and pressure relief devices often need to be tested to determine or verify the exact pressure at which the product either opens by design or ruptures due to pressure stressing.

Depending on the product, a burst test can be destructive or nondestructive. The problem facing test engineers is coming up with a way to slowly increase pressure and then record the precise pressure at which the product opens (the peak-hold burst pressure).

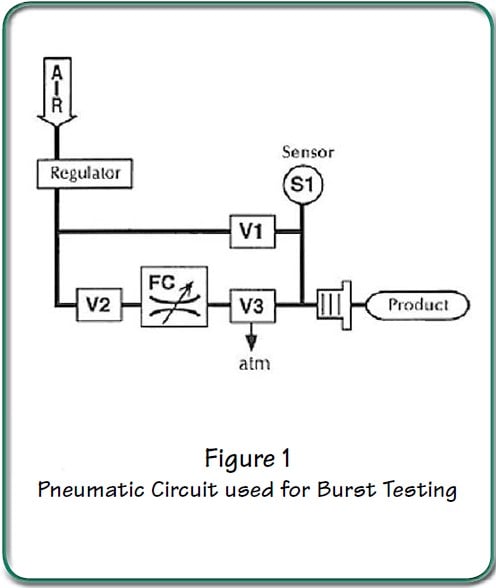

Uson test equipment conducts burst testing using one of two basic methods. Sprint iQ testers can be outfitted with either manual flow control valves or with electronic regulators that supply the required ramping pressure. This Application Note describes how burst testing is accomplished using a manual regulator and a precision flow control.

When configured for burst testing, the Sprint iQ tester contains all the electronic and pneumatic controls to perform burst testing on a wide variety of products.

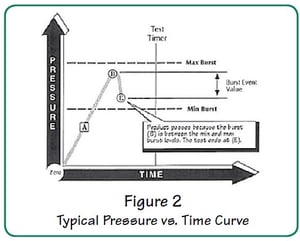

Pressure slowly ramps up through the flow control and pressurizes the product shown by curve A moving from zero and approaching the point at B (Figure 2). Sprint iQ consistently captures pressure readings during the pressure increase. When the pressure suddenly drops more than the burst even value E, Sprint iQ stops the test and displays the maximum pressure attained. The pressure drop limit entered into the tester’s program is called the “Burst Even Value.” This value is a small pressure (such as 0.2 psig) and is not represented as a fixed point on the scale. For product to pass the burst test in our example, the part must burst at a point greater than the minimum burst level (lower dashed line) and at a pressure that is less than the maximum burst level (upper dashed line).

If Sprint iQ does not detect an even (pressure drop below the burst even value) within the established test time, the program times out and Sprint iQ shows NO BURST in the status box on the display.

If Sprint iQ detects an event (pressure drop below the burst event value) at a pressure that is below the minimum burst pressure, then it shows LO BURST in the status box on the display.

Sprint iQ burst testers are used for testing products such as one-way valves or devices that open rapidly under applied pressure. Consider using a Sprint iQ burst tester for applications in which the need to record a peak pressure is important. The test could be destructive or non-destructive. A downstream sensor option can be added to the burst machine to test products that have a second air connection. Please see the Application Note Titled Downstream Sensor Option for more information about testing with a second pressure sensor downstream from the product.

Sprint iQ Burst Tester Features

How to convert bubbles to flow units using a quantified leak rate with the mass flow test method.

The Sprint iQ bidirectional check valve tester is equipped with a precision flow control and two pressure sensors.

The Sprint iQ check valve tester is equipped with a flow control and an additional transducer called a downstream sensor..

Industries