Differential Vacuum Decay Test

What is a Differential Vacuum Decay Leak Test?

Differential vacuum decay test works similar to the differential pressure decay test except that the system is evacuated using an internal or external vacuum.

How is a Differential Vacuum Decay Test Performed?

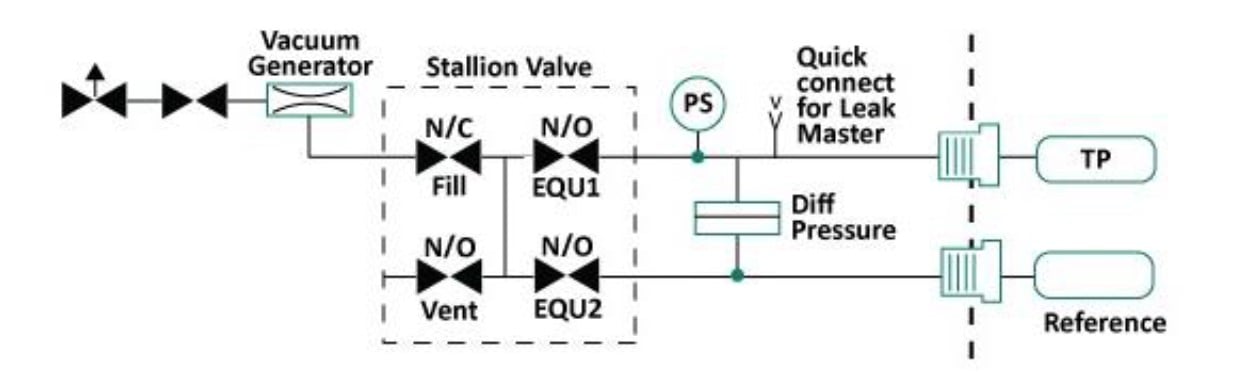

The part to be tested [TP] is attached to the test port, the non-leaking reference part is connected to a separate test port and the test is started. The tester evacuates the part and reference with negative pressure [-P] to the desired test pressure set by opening the fill valve and the equalization valve (EQU2) and closing the vent valve during the Fill step.

At the end of the Fill step, pressure is then trapped inside the part and reference. The fill valve, EQU1 and EQU2 valve are closed.

Trapped pressure inside the test circuit is held through the Stabilize step and then measured by the testers differential pressure transducer during the Test step.

If the part exceeds the programmed leak tolerance (pressure rise over time or quantified leak rate), the testers display indicates the reason for the test failure and displays the pressure gain or leak rate in user defined units of measure.

At the end of Test step, the part and the reference are equilibrated to the atmosphere by opening EQU1, EQU2 and the vent valves, and the tester is ready to make the next test.

Testers Supporting Differential Vacuum Decay Tests

The SaaS Sales & Marketing Acronym Bible

Industries

English

English

简体中文

简体中文

Deutsch

Deutsch

Español

Español

.jpg)