Occlusion Testing

Occlusion testing is the functional testing of products to ensure pathways are open and have not become blocked or partially obstructed.

Coming up with ways to quickly connect products to test instruments and still maintain leak-tight seals is a common challenge facing test engineers. The question becomes: “How do I get my product hooked up to the tester in a way that’s fast, simple to control, leak tight, and within my budget?” Integrity testing by its very nature means connections must allow no leakage. Also, connecting products to the measuring instrument must be made in a way that can be controlled by the tester and not slow down the test operation.

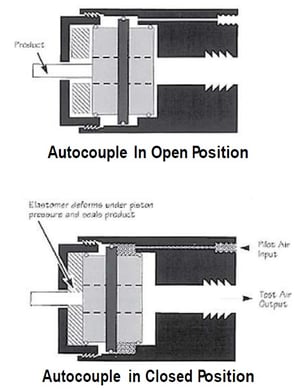

Uson recommends using a line of sealing devices known as autocouples. These devices generate leak-tight seals on smooth tubes and even on rough and irregular surfaces. Because the seal is activated by air pressure, the tester can easily control the clamping.

Diverse sizes and configurations for both inside and outside sealing are available. Autocouple devices are perfect for connecting products to the tester in a wide range of test situations.

Autocouple devices can be mounted remote from the tester or attached directly to the tester.

Applications

ApplicationsConsider using an autocouple device when testing products that are relatively small (under 6 inches in diameter) and fairly uniform.

Autoocuple PrexSeal devices work well with the following applications:

Occlusion testing is the functional testing of products to ensure pathways are open and have not become blocked or partially obstructed.

This Application Note describes how burst testing is accomplished using a manual regulator and a precision flow control on the Sprint iQ leak tester.

Uson pressure booster offers a safe, quiet and cost-effective alternative to renting gas bottles or buying a clean, high-pressure, motor-driven...

Industries